Computational Fluid Dynamics (CFD) simulations, a computer-based numerical approach, play a major role in understanding and optimising the performance of Heating, Ventilation, and Air Conditioning (HVAC) systems within diverse environments and operating conditions.

CFD simulations, in essence, involve the application of numerical methods to analyse the behaviour of fluid flow, heat transfer, and other related phenomena.

When specifically applied to HVAC systems, these simulations provide valuable benefits to all stakeholders involved in a project:

- Ensure that your design will work as planned with a high degree of

- Optimise the system without increasing laboratory infrastructure and prototyping costs.

- Analyse spaces with complex phenomena where tests cannot be conducted.

- Minimise the operation costs of the installation while improving

- Receive fully tailored support and advice from a dedicated team of CFD experts.

- Facilitate early-phase design decisions.

- Gain knowledge about complex air diffusion phenomena.

CFD simulations have numerous applications when used in HVAC systems. Below we would like to take you through a number of situations where CFD simulations provide valuable insights.

Comfort

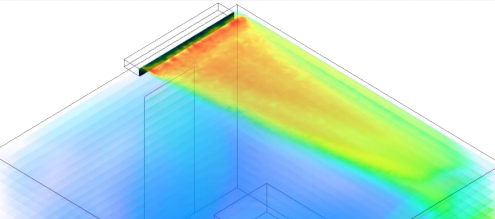

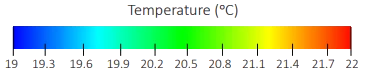

Simulations can analyse the comfort of occupants. By evaluating variables such as velocity, temperature, or relative humidity, CFD simulations offer a comprehensive analysis. This includes a focused examination of various ventilation techniques, including mixed ventilation, displacement ventilation, and exposed CFD proves instrumental in comparing and understanding the differences in velocity and temperature among these systems. This insight allows engineers to optimise system design effectively, enhancing the overall comfort index.

In this project, thermal comfort was analysed in a restaurant. Temperatures contours were evaluated at people seats.

Air Quality

CFD allows the study of indoor air quality in In these studies, the air quality is a critical variable, useful for identifying zones with insufficient air renewal and calculating ventilation efficiency. Simulations can also be used to evaluate the distribution of contaminants, pathogens, or CO2. Notably, CFD proves useful in analysing systems with induction units, where primary air induces secondary air for treatment, helping in optimising ventilation and ultimately contributing to enhancing people’s health.

COVID infection probability was studied in an office for this project, using displacement ventilation. Contours show how the risk of infection is higher above the infected person.

Thermal Loads

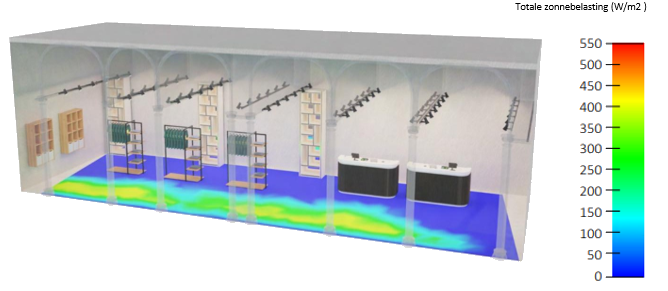

In buildings with large glazing, solar rays can impact internal temperature distribution, affecting occupants’ thermal CFD simulations enable the comprehensive evaluation of elements such as glass coatings, curtains, etc., to mitigate radiation and achieve the final optimisation of the entire system.

For this study, the effect of solar radiation was evaluated. Glazing on the facade of the ground floor of a shop- ping centre allowed solar radiation to heat the occupied zone, raising the temperature.

Optimisation

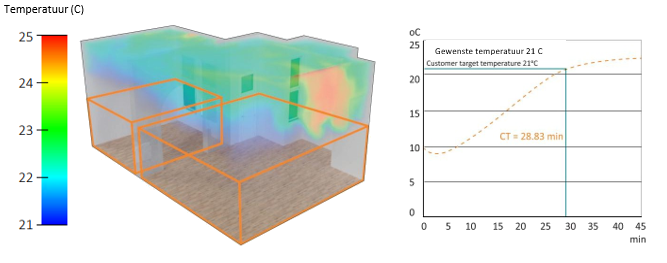

Simulations can be used not only to study steady state conditions, but also in transient scenarios. This enables the analysis of the temporal evolution of different variables and provides a valuable tool for optimising Building Management Systems (BMS) controls. For instance, it can determine the optimal lead time for starting the cooling/heating system to achieve the setpoint Another practical application involves assessing the required operational time for a system to effectively reduce pathogen concentration to a specified level.

For this hotel room, a transient simulation was performed. The target was to identify the necessary time to

reach comfort temperature.

Troubleshooting

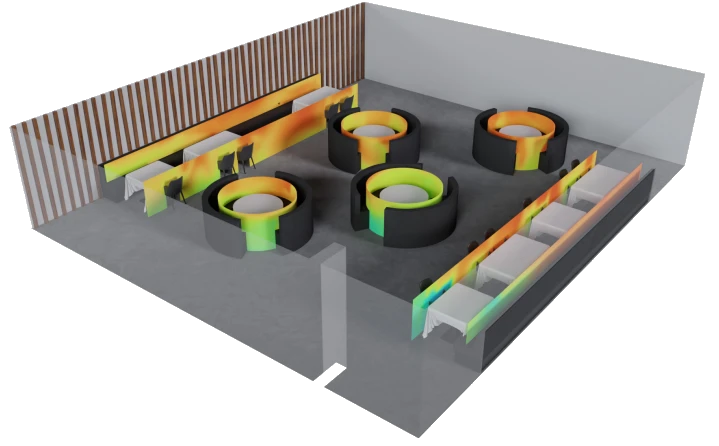

In instances where a malfunction in an implemented HVAC system is causing discomfort, noise, or other issues, and the cause is uncertain, CFD analysis can swiftly identify the problem and propose solutions. This application is particularly valuable for enhancing the performance of previously installed systems.

Two supply systems were compared in this museum gallery. Velocities near the main paintings had to be as lowest as possible. CFD allowed to decide the best option.